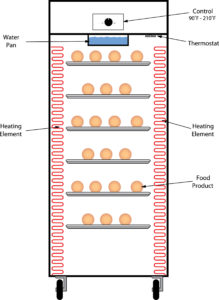

To explain, holding cabinets are heated appliances designed to hold cooked foods at a safe serving temperature.

Some holding cabinets do this job well and some do not. Of course, the quality depends on the manufacturer and design. Also, holding cabinets are sometimes referred to by other names. For instance, they are called a hot box, warmer, insulated warmer, hold and serve, warming cabinet, and other phrases.

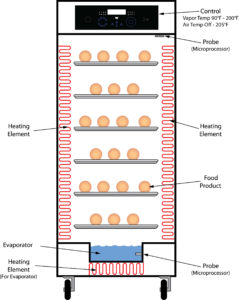

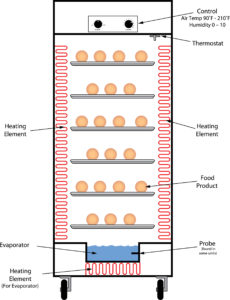

Winston’s CVap® technology started as a holding technology. The challenge was to create an appliance that could keep foods hot and fresh. For example, operations with a drive-thru service rely on holding units to keep food hot and ready for fast delivery. Winston’s founder, Winston Shelton, saw the benefit of the technology. He worked out the science behind the challenge. As a result, CVap technology has been an industry leader ever since.