Efficient Kitchen Design Ideas for Maximum Efficiency

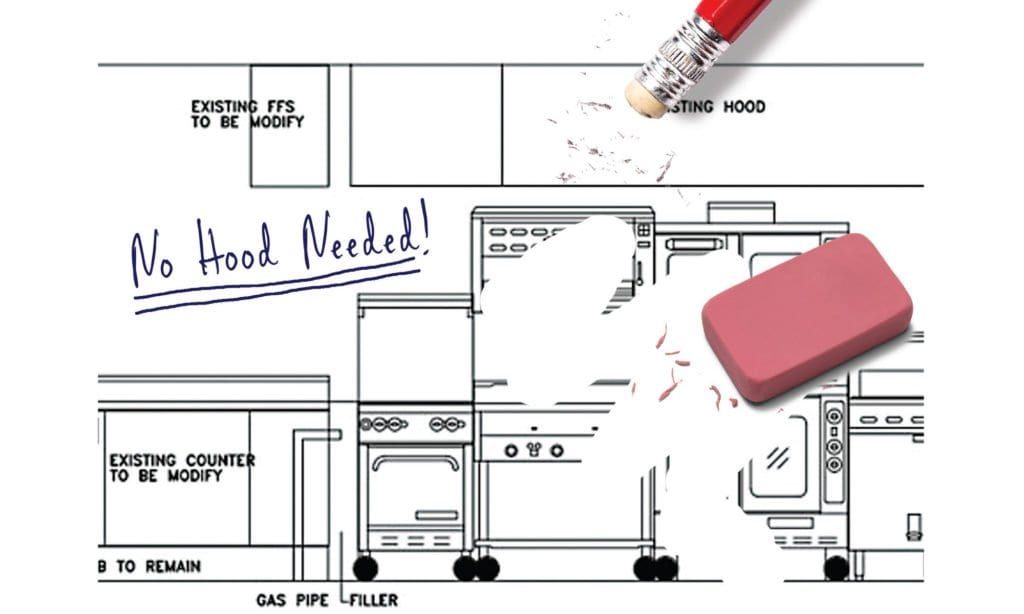

Maximizing efficiency in your kitchen design takes planning, research, and hard work. Whether your operation is in the blueprint stage or undergoing a remodel, the pressure to get it right can be intimidating. Winston has the tools to help assure kitchen efficiency. Why is Having an Efficient Kitchen Design Important for Your Restaurant? Efficiency has […]

Efficient Kitchen Design Ideas for Maximum Efficiency Read More »