Head-to-Head:

Why the Winston LP56 Outperforms the Henny Penny PFE-500

in High-Volume Chicken Frying, and the Truth About Built-In Filtration

Executive Summary

In the fast-paced world of high-volume foodservice, consistency isn’t optional, it’s everything. To deliver top tier fried chicken, you need equipment that keeps up without exhausting your crew or blowing your budget. This white paper compares the Winston LP56 to the Henny Penny PFE-500 and explains why the LP56 doesn’t just compete, it outperforms. Faster cook times, minimal downtime, and easier cleanup make the LP56

the smarter, more efficient choice.

Why Pressure Frying Still Reigns Supreme Before diving into specific fryer models

Let’s get one thing straight: pressure frying is still the gold standard for high-volume fried chicken. It doesn’t matter whether you’re using a Winston or a Henny Penny, the core advantages of pressure frying chicken speak for themselves:

- Faster cook times

- Juicy, tender meat with that perfect crispy crust.

- Less oil absorption.

- Consistent flavor and texture, batch after batch.

- A safer, cleaner kitchen environment.

The bottom line: Pressure frying delivers unbeatable consistency, quality, and speed, regardless of the brand. But when you look at the details, not all pressure fryers are built the same. Let’s break down why the Winston LP56 leads the pack.

1. Cooking Capacity: More Bird. Less B.S.

Let’s break it down. The Henny Penny PFE-500 is a 4-head fryer that maxes out at 32 pieces of chicken per batch. Respectable, but not game-changing.

On the other hand, Winston LP56 handles up to six heads per batch – that’s up to 48 pieces of chicken. Same footprint, same crew, 50% more chicken. Boom.

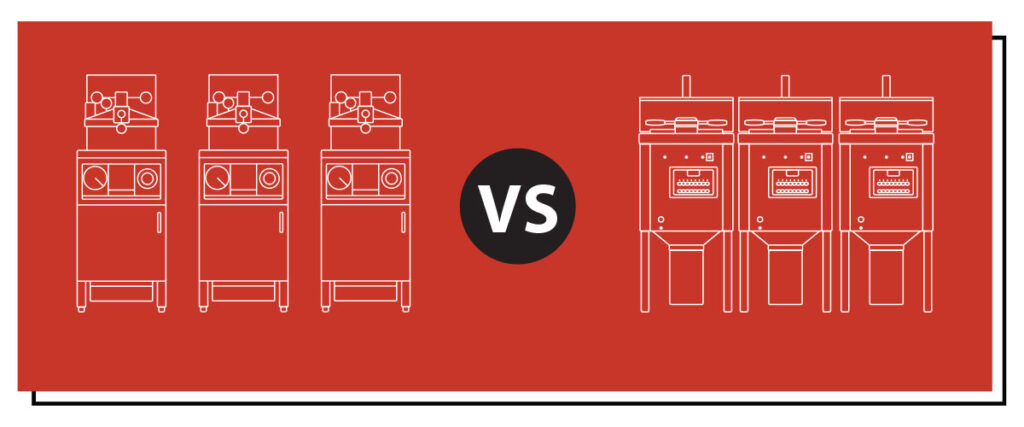

Let’s do the math on a 3-fryer setup:

- Three Henny Penny fryers, cooking 32 pieces per batch, yield 96 pieces every 15 minutes.

- Three Winston LP56 fryers, cooking 48 pieces per batch, crank out 144 pieces in the same

amount of time.

Translation? Winston crushes Henny Penny on production. It only takes two Winston fryers to match the output of three HP units. And that’s before we talk about energy use, oil consumption, maintenance, or overall cost.

By skipping that third fryer alone, you’re saving over $20,000* in equipment cost, up front. That’s not even counting all the extra accessories you’ll have to buy from Henny Penny to get the PFE-500 up and running. Fryer baskets, shelves, brushes, and even the handle; none of it is included when you buy from Henny Penny.

No hidden surprises. No extra runs to the supplier.

With Winston, it’s a different story.

Once your fryer is installed and connected to power, you’re ready to rock and roll. Every LP56 comes standard with:

- Basket and shelves

- Drain hook

- Gloves

- Brush and cleaning tools

- Gaskets

The only things you need to supply are the chicken, oil, and breading.

Bottom line: With Winston, you’re cooking more, saving money, and avoiding unnecessary hassle, right out of the gate.

Advantage: Crank out more chicken, with fewer fryers, less hassle, and lower capital investment.

*Based on July 2025 Published Pricing

2. Continuous Cooking: 75% More Chicken, Zero Downtime

The Henny Penny PFE-500 requires filtration every three to four batches. That process involves draining the oil, cleaning the pot and cold zone, then refilling and reheating. Each cycle takes about 15 minutes and brings cooking in that fryer to a halt.

During that same window, the Winston LP56 keeps going and can crank out another full 6-head batch, up to 48 more pieces. You can cook all day without filtering.

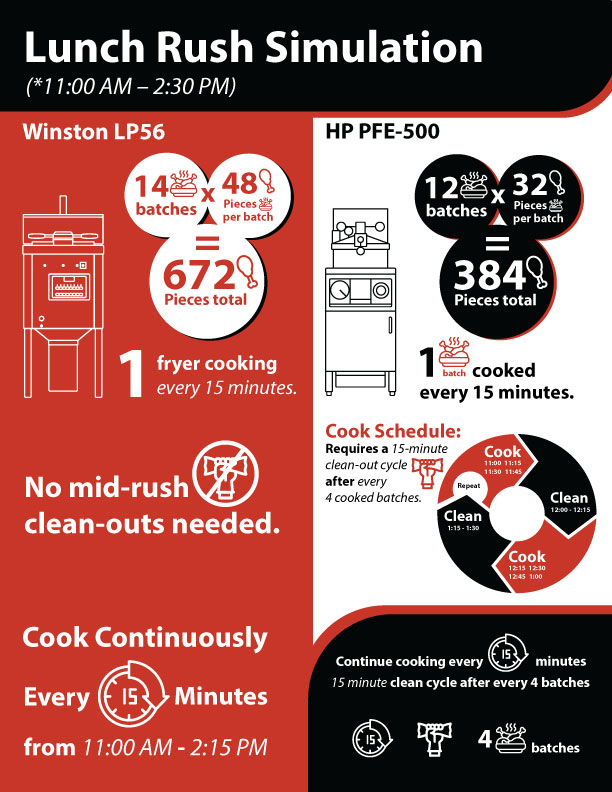

Lunch Rush Simulation (11:00 AM – 2:30 PM):

One Henny Penny PFE-500

- 12 batches × 32 pieces per batch = 384 total pieces

- One batch cooked every 15 minutes.

- Requires a 15-minute clean-out cycle after every four cooked batches.

- Cooking/Cleaning Schedule:

Cook: 11:00, 11:15, 11:30, 11:45

Clean: 12:00–12:15

Cook: 12:15, 12:30, 12:45, 1:00

Clean: 1:15–1:30

Cook: 1:30, 1:45, 2:00, 2:15

Clean: 2:30

One Winston LP56

- 14 batches × 48 pieces per batch = 672 total pieces.

- One fryer cooking every 15 minutes.

- No mid-rush clean-outs needed.

- Cooking Schedule:

Cook continuously every 15 minutes from 11:00 AM to 2:15 PM

Summary:

In the same 3.5-hour window, one Winston LP56 cooks 75% more chicken than one Henny Penny fryer, with fewer interruptions and zero downtime for cleaning. Just cook, cook, cook.

Now let’s compare the production of having two fryers in that same time span:

- Two Henny Penny fryers: 768 pieces

- Two Winston LP56 fryers: 1,344 pieces

That’s 288 more 2-piece fried chicken meals served per lunch period.

Advantage: At $5.00 per meal, just the extra revenue from additional Winston production is over $1,400 in sales per day. At this rate, you could pay off two Winston fryers in less than two weeks. Yes, just two weeks from incremental lunch sales alone.

Advantage: Continuous cooking without downtime allows Winston to dramatically outperform during rush hours.

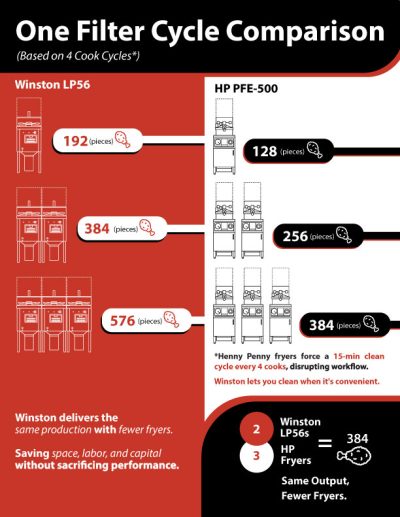

One Filter Cycle Comparison (Based on 4 Cook Cycles)

| FRY COUNT | BRAND | TOTAL PIECES COOKED |

|---|---|---|

| 1 FRYER | HENNY PENNY | 128 |

| 1 FRYER | WINSTON | 192 |

| 2 FRYER | HENNY PENNY | 256 |

| 2 FRYER | WINSTON | 384 |

| 3 FRYER | HENNY PENNY | 384 |

| 3 FRYER | WINSTON | 576 |

Same Output, Fewer Fryers

Configuration Total Pieces

3 HP Fryers 384

2 Winston LP56 384

Takeaway:

Winston delivers the same production with fewer fryers, saving space, labor, and capital, without sacrificing performance.

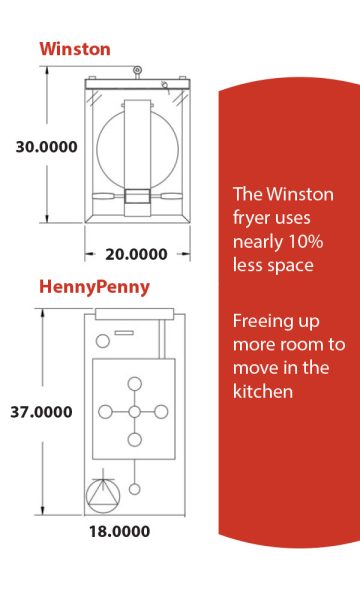

3. Footprint and Layout Optimization

The Winston LP56 has a slightly smaller footprint and takes up less space than the Henny Penny PFE-500, making it a better fit for tight or high-traffic cook lines. Because each LP56 delivers higher output per batch, operators can often reduce the number of fryers needed without sacrificing capacity.

Fewer fryers mean more available floor space, lower utility consumption, and reduced investment in hoods, ventilation, and support equipment.

Advantage: Smaller footprint, higher throughput, and smarter use of space for a more efficient, cost-effective kitchen.

4. Simplified Filtration and End-of-Day Cleanup

When it comes to fryer maintenance, the difference between Winston and Henny Penny is night and day, especially during high-volume shifts. With Winston, there’s no mid-rush shutdowns, no stopping to filter, and no pulling staff off the line. You just keep cooking. Zero interruptions. Maximum productivity.

Winston LP56 End-of-Day Process:

- Drain oil.

- Rinse the pot with hot oil while filtering or polishing the oil.

- Clean one shared external filter tank (yes, only one filter to clean even if you have multiple fryers).

That’s it. No extra steps. No downtime during the rush.

Henny Penny PFE-500 Process:

- Filter every three to four cooks (about 15 minutes each).

- Repeat multiple times during peak hours.

- Clean each fryer and its built-in filter tank at the end of the day.

In a busy non-stop kitchen, a operator will be required to clean a PFE-500 up to six times per day (lunch and dinner), adding 90+ minutes of fryer cleaning-related labor before nightly cleanup even begins. What could you do with an extra 90 minutes from your staff every day? Focus on better chicken and making more sales, not cleaning fryers.

As one franchisee put it: “Are you cleaning fryers during the rush, or cooking chicken to sell? What sounds better to you?”

And don’t forget the difference between design:

- Henny Penny: Square pot = more corners, more scraping

- Winston: Round pot = smoother draining, easier cleaning

Advantage: Winston simplifies daily maintenance, saves labor, and improves ergonomics.

5. Rush-Ready Performance

The Winston LP56 is engineered for nonstop, high volume cooking. No waiting. No lag. Just consistent performance when it counts most.

Here’s what that means in the real world:

- No heat loss between batches.

- No recovery time or reheat delays.

- No mid-shift cleaning disruptions.

Advantage: Always hot. Always ready. Winston doesn’t flinch when the rush hits.

6. Total Cost of Ownership

The sticker price is just the beginning. The Winston LP56 delivers real savings every single day:

- Lower labor costs with fewer cleanouts and simpler maintenance.

- Extended oil life for better margins.

- Higher hourly output with fewer fryers.

- Smaller footprint means reduced utility and ventilation expenses.

Over time, these advantages add up fast.

Advantage: Faster ROI, lower operating costs, and more profit per pound. Winston doesn’t just cost less, it earns more.

7. Simplified Training

How You Fry Matters: Safer, Simpler, and More Consistent Training & Execution Training shouldn’t feel like a game of telephone. But with traditional pressure fryers like Henny Penny, that’s often the case.

Here’s what your team deals with Henny Penny:

- Chicken is hand-dropped into hot oil, usually in a specific sequence and fryer position to ensure even cooking.

- The cook must shake the basket to prevent pieces from sticking together.

- The lid is closed to pressure cook the batch.

Now compare that to the Winston LP56:

- Chicken is breaded and loaded onto racks; no hand-dropping, no shaking, no stirring.

- The basket with racks of breaded chicken slide into place in the fryer in one smooth motion, and the lid closes.

- After the cook cycle, the basket and racks lift out as easily as they went in, with chicken still neatly arranged.

- Simply transfer the racks to the hot hold tray, no dumping, no scrambling, no mess.

It’s not just easier in. It’s easier out.

And once it’s done?

- The basket is lifted manually out of the hot oil.

- The cook has to tilt and dump the chicken out (hoping it doesn’t hit the floor).

- Pieces must be rearranged on a tray before they can be moved to the hot hold cabinet for sale.

And between batches?

- A quick brush of the elements and a scrape of the crumb line (right into the oil) are all that’s needed.

- No mid-shift filtration required, just a light pot cleaning and end-of-shift filter.

Plus, the external Winston filter can be shared between multiple fryers, saving money and kitchen space.

Where are you using your labor?

Winston gives you:

- A consistent, repeatable SOP.

- Faster onboarding and fewer mistakes.

- Less strain and fewer steps for your staff.

- A better chicken experience from fryer to hot hold.

Which system would you rather bet your kitchen’s consistency on?

Advantages: Easier Training, Safer Execution, and More Consistent Chicken from Day One.

8. Side-by-Side Comparison

| Feature | Henny Penny PFE-500 | Winston LP56 |

|---|---|---|

| Heads per fryer: | 4 | Up to 6 |

| Pieces per 3-fryer batch: | 96 | 120–144 |

| Filter cycle frequency: | Every 3–4 cooks | Every 20–25 cooks |

| Filter downtime (during open times): | ~15 min (active labor) | None |

| End-of-day tanks to clean: | 3 | 1 |

| Footprint: | 4.63 Sq. Ft. * | 4.17 Sq. Ft. (10% less space than HP) |

| Peak cooking capability | Interrupted | Uninterrupted |

| Training complexity | Medium–High | Low |

* Does not include required 6-inch clearance on one side

Bottom Line: Winston delivers more capacity, fewer interruptions, simpler cleanup, and easier training, all in a smaller footprint.

Conclusion

The Winston LP56 doesn’t just meet the industry standard, it raises it. With greater capacity, uninterrupted performance, faster cleanup, and lower operating costs, it’s engineered for kitchens that demand more.

Whether you’re running one location or hundreds, the goal is the same: serve more chicken with less hassle. And that starts with a fryer built to keep up.

Winston LP56. Built to outperform. Designed to outlast. Ready when the rush hits.

Want to unleash the power of Winston fryers in your operation? Let’s chat!

Frequently Asked Questions (FAQ)

How does the Winston 6-head fryer achieve higher production rates than the Henny Penny 4-head fryer?

Winston’s larger cook capacity, faster recovery time, and reduced cleaning interruptions allow for more continuous cooking cycles and significantly more chicken served per hour.

What is the actual labor impact of the Henny Penny clean-out cycle?

The 15-minute cleaning cycle on Henny Penny is not just downtime. It requires dedicated labor to drain oil, clean the pot, empty the cold zone, and reheat. That’s 15 minutes of focused staff time per clean, which could have been spent cooking another full batch in the Winston.

How often does the Henny Penny fryer require cleaning during a lunch rush?

Typically, every four full cooks trigger a required clean-out. In a high-volume lunch shift, this may mean multiple interruptions.

What kind of savings or revenue gains are possible with the Winston fryer?

Based on the simulation, Winston fryers can produce over $3,000 more in chicken sales per day during lunch, meaning a 2-week ROI is possible just from increased production capacity and uptime.

What is the footprint difference between the two fryer models?

Despite higher production, the Winston 6-head fryer maintains a comparable footprint to traditional 4-head models, making it a higher-efficiency option without needing additional kitchen space.

Do both fryer models use the same oil capacity or filtration system?

Winston fryers are designed with operator-friendly filtration and oil management, often leading to longer oil life and simpler maintenance. Specific models may differ, so side-by-side specs should be reviewed.

Can operators be trained quickly to switch to Winston fryers?

Yes. Operators often report easier usability, less downtime, and more intuitive operation with Winston models, especially appreciated during peak periods.

What maintenance is required during peak periods with the Winston fryer?

Unlike Henny Penny models that demand full clean-outs mid-rush, Winston fryers require no filtration during peak service. Just brush the elements, scrape the crumb line (allowing debris to fall into the oil), and that’s it. Seriously, that’s it. At the end of the shift, a light pot cleaning and standard oil filtration are all that’s needed.

How does this affect customer wait time during peak service?

With fewer interruptions and larger batch sizes, Winston fryers allow for faster order fulfillment and shorter customer wait times during high-traffic periods like lunch.

Where do I store the mobile filter? My kitchen is too small. I need a built-in filter to save space.

That’s the beauty of Winston. Yes, the LP56 uses an external filter, but you don’t need it during the day. You can store it in a closet, storeroom, or anywhere out of the way until it’s time to close. No mid-day filtering required. And if you have more than one fryer, or other fryers like a dedicated French fry cooker, the Winston filter can work with those too, saving you serious money compared to buying a motor and pump for every fryer.

What support does Winston offer for transition, training, and setup?

Winston provides detailed onboarding materials, in-field support, and rep training to help operators fully maximize the equipment from day one.

Am I ready to cook as soon as my fryers are installed?

With Henny Penny’s PFE 500, no. You’ll still need to order all the necessary tools and accessories separately before you can cook your first batch.On the other hand, once your Winston fryer is installed, you’ve got everything you need to get cooking.

Does my fryer need to be placed under a hood or have ventilation?

Yes. Both Winston and Henny Penny fryers require proper ventilation and hood placement to comply with local health, safety, and fire codes. This isn’t a brand-specific requirement, it’s a standard commercial kitchen necessity for pressure fryers. Make sure to consult with your local code authority or installer to ensure full compliance and safe operation.