Foodservice operations are facing stiff headwinds. Rising food costs, labor shortages, wage growth, and constant turnover put pressure on profits. We experimented to prove that CVap® Technology can help operations overcome these challenges.

Hypothesis:

An end user’s food and labor costs can be decreased by using CVap technology due to the efficiency of holding and staging menu items, using delayed starts, and staff training. The target was to reduce ticket times to under ten minutes, without sacrificing food quality.

Experiment:

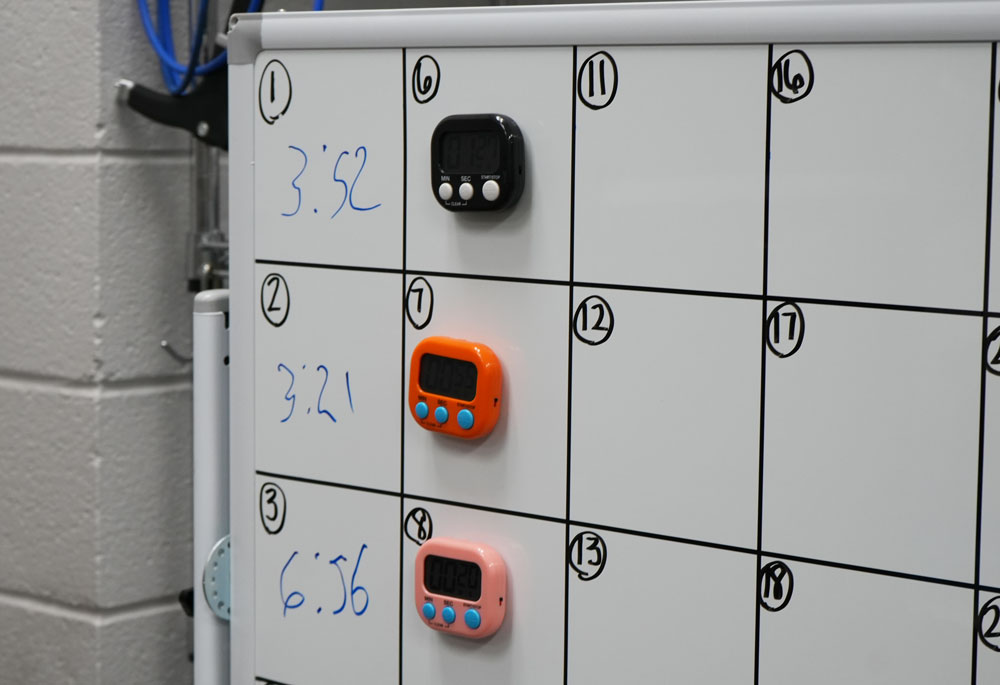

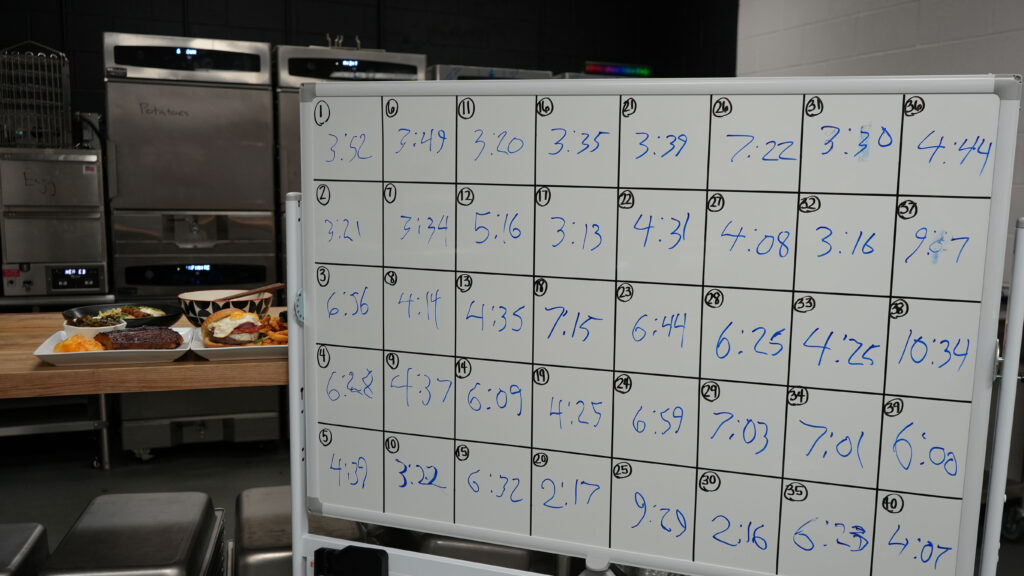

Develop a prix fixe menu utilizing food items that highlight various CVap capabilities, i.e. sous vide, roasting, braising. Take pre-cooked and post-cooked weights of all proteins being processed to measure yields. Set timers and stopwatches to monitor ticket times of all menu items and the finishing of each order placed during mock restaurant-style lunch service.

We wanted to prove the following:

1. Ticket Times – CVap ovens can deliver shorter ticket times than traditional cooking equipment.

2. Reduced Food Waste – CVap’s extended holding capabilities extend the amount of time food can be

held without degrading. This can significantly reduce the amount of food operators are forced to throw away.

3. Reduced Labor Costs – CVap technology provides operators with the tools to reduce the amount of staffing necessary to run an effective kitchen. Processes such as overnight cooking, automatic hold, and staging enable staff to multitask without sacrificing food quality.

Analysis:

Record all data collected during the preparation and execution of lunch service.

Conclusion:

Compare an estimated time and cost of executing menu in a traditional kitchen vs. the Winston kitchen

using data collected from experiment.

Tools Used:

CVap® RTV5-05UV Retherm Oven

CVap HOV5-05UV Holding Cabinet

Collectramatic® LP56 Fryer

Gas Grill

Digital Timers

The Staff:

3 Back of House (BOH)

2 Front of House (FOH)

The Customers:

40 Winston employees, spread out over a two-hour span in 10-minute intervals.

The Recipes:

Labor Costs: The Math

Winston Kitchen

Labor Cost: Prep (2.5 hrs day before & 2hrs day of )

- Avg Hourly Rate @ $19

- 6 Prep Cooks for 4.5 hours

- 27 Labor Hours x $19 per hour= $513

Labor Cost: Lunch Service

- 3 BOH for 1.5 hours @ $19= $85.50

- 2 FOH for 1.5 hours @ $13= $39

Total Labor = $637.50

Labor Savings: 14%

Traditional Kitchen

Labor Cost: Prep (2.5 hrs day before & 2hrs day of )

- Avg Hourly Rate @ $19

- 6 Prep Cooks for 4.5 hours

- 27 Labor Hours x $19 per hour= $513

Labor Cost: Lunch Service

- 6 BOH for 1.5 Hours @ $19 = $171

- 3 FOH for 1.5 Hours @ $13 = $58.50

Total Labor = $742.50

The Results

Our experiment proved successful. We were able to show in a real-world setting that utilizing CVap to stage food ahead of time enabled us to provide a full lunch service with substantially fewer staff than would ordinarily be needed. This resulted in a 14% savings on labor costs. The average ticket time was just over five minutes, well below the ten-minute target. And post-experiment polling revealed that our customers were overwhelmingly pleased with the taste and quality of their food, as well as the time it took to serve it. CVap saved time and labor without sacrificing food quality.

Summary:

We were able to prove in a real-world setting that utilizing CVap to stage food ahead of time enabled us to

provide a full lunch service with substantially fewer staff than would ordinarily be needed for a

traditional meal service. This resulted in a 14% savings on labor costs.