Commercial pressure fryers have been around for decades. Colonel Harland Sanders was the catalyst behind the development of commercial pressure fryers. Among his favorite cookers was the Collectramatic®, designed by Winston’s founder, Winston Shelton. Shelton perfected the early fryer designs of the 60s, creating the fryer that the Colonel preferred. Over 50 years later, the Collectramatic brand is still going strong.

Here are some interesting facts about pressure fryers.

FACT #1

Tough Old Birds

When fried chicken first became popular as a fast food, the poultry industry wasn’t what it is today. Back then, chickens took nearly twice as long to grow to maturity. That extra time meant they built up a lot of collagen and connective tissue, making the meat tougher. Because pressure frying raises the boiling temperature of the water, it helps the chicken’s internal moisture to break down that tissue, tenderizing the meat.

Fast forward to today. Poultry matures in about half the time as in the 50s and 60s. The high pressure and temperatures needed to cook the old birds are no longer needed. Since the birds are not as tough, cookers can use a lower pressure to get the same tender results. Being able to cook at lower pressures and temperatures reduces energy consumption and makes for a safer kitchen. Lowering the cooking temperature also extends the cooking oil’s life, helping operations be more profitable.

FACT #2

Put a Lid on It!

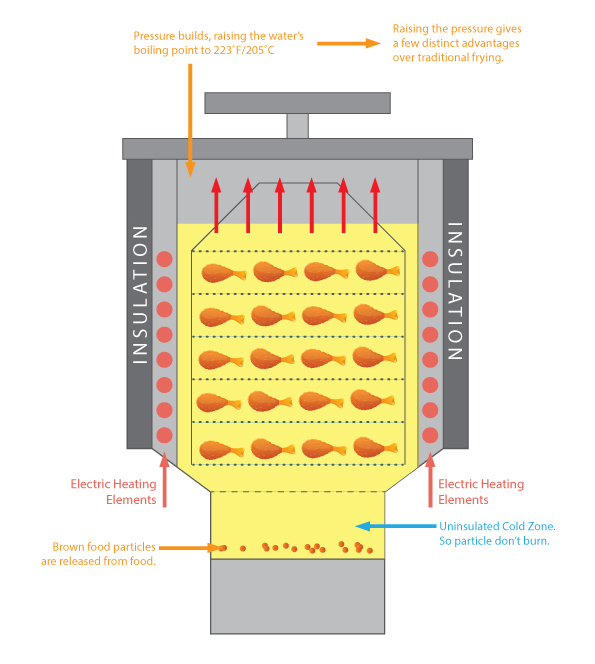

The lid on a pressure fryer seals the cooking vessel, allowing pressure to build. This is critical because once pressure builds, it raises the boiling point of water. Raw chicken, by its nature, is a pretty moist product. The chicken itself provides the steam generated during cooking. As pressure rises, less of the chicken’s moisture is lost, and it cooks faster. The end product is more tender and juicier than open-fried chicken.

There’s also a balance of pressure going on inside the pressure fryer. The pressurized cook pot forces hot oil at the surface of the food. But moisture within the food is also trying to expand as it cooks, creating an opposing pressure. The effect is two-fold. The food’s internal pressure balances the external pressure. This speeds up cooking and prevents the food from soaking up much excess oil.

FACT #3

It's Not Just for Bone-in Chicken

While it is true that the vast majority of product cooked in pressure fryers is bone-in chicken, that’s not the only food that can be cooked in them. Boneless items like chicken filets, tenders, and nuggets are also excellent when cooked in a pressure fryer. And pressure fryers aren’t limited to chicken. Proteins with natural juices like steaks, ribs, and pig’s wings can be pressure fried. Potato wedges are also the bomb when pressure fried.

FACT #4

Pressure Fryers Can Do Double-duty

Many pressure fryers are only capable of pressure frying. However, Collectramatic pressure fryers can both pressure fry and open fry. Open frying is as easy as leaving the lid up. Certain foods produce better results when open-fried. These tend to be foods with heavier breading or more delicate foods like fish, shrimp, or french fries.

Being able to both pressure fry and open fry in the same unit is beneficial for operations with tight space constraints. It offers the best of both worlds.

FACT #5

Pressure Frying Extends Oil Life

You might think that pressure and open fryers consume equitable amounts of oil. But pressure fryers are more frugal with their oil. It’s because of oil’s chemistry.

There are three culprits when oil breaks down – heat, air, and moisture. Pressure frying helps with all three. Pressure fryers cook at a lower temperature, which helps prevent scorching. Having the lid down and the fryer under pressure minimizes the contact between the air and the oil, reducing the oil’s oxidation. And because pressure frying seals most of the food’s moisture inside the food, it cuts down on the degradation of oil by water contamination.

FACT #6

Pressure Frying Makes Food Less Greasy

Any time you use oil as a cooking medium, there is a potential for greasiness. But if cooked properly, pressure-fried food isn’t greasy. This can be minimized by managing the temperature of your cooking oil.

Most operators use a stair-step approach to oil temperatures. Food starts in the fryer at a higher temperature, which generates steam (and pressure), and helps the breading set on the food. Next, the oil temperature is dropped so that the food can cook thoroughly without burning the breading. This temperature management will minimize the amount of oil that is allowed to soak into the food. Because moisture is sealed within the food, it emerges juicy, not greasy.

While food that has been open-fried can be crispy, the higher amount of oil that can soak into the food while it’s cooking means that this food will lose its crispiness after a short time, making it unsaleable.

FACT #7

Round Fry Pots are Naturally Better

Fry pots come in two basic shapes: round and rectangular. For a variety of reasons, round pots are the better option. Round pots allow the entire cooking vessel to be encircled with heating elements. This facilitates even heat distribution and better oil circulation.

Round pots are inherently more durable. A round vessel only requires one weld seam. Seams are naturally the weakest point in the pot wall. While actual seam failures are rare, they can happen. It’s the reason most manufacturers place a limit on a pressure fryer’s helpful lifetime. Collectramatic round pots have operated in restaurants for up to 25 years. Rectangular pots require multiple seams, increasing the odds of future problems. Round pots just last longer.

FACT #8

Mo' Pressure, Mo' Flavor

Pressure frying naturally imparts better flavor to food. As mentioned previously, open frying can transfer the oil’s flavor to the food, overpowering the food’s natural flavors. In contrast, pressure frying seals in the food’s natural flavors and prevents excess oil intake. This results in better flavor and allows the food to lock in moisture.

FACT #9

Consistently Good

Consistency is critical in commercial kitchens. Your customer expects the same high quality every time they visit your operation. Pressure fryers make that possible. The sealed environment of a pressurized fryer allows you to cook at the exact pressure and temperature you want. Computerized controls remove all the guesswork.

In contrast, open fryers are subject to variations in their environment (ambient temperature, barometric pressure, etc.) that can have a negative effect on the fryer. Consistency is much easier to achieve under pressure.

FACT #10

Keeping Costs in Check

Pressure fryers are simply more efficient than open fryers. They use less oil and make that oil last longer. They have shorter cooking cycles, which saves electricity. And chicken cooked in a pressure fryer stays fresh longer, which reduces waste. Pressure fryers are an all-around win-win.

Want to know more about pressure fryers? Fill out our contact form, and we’ll be glad to talk to you about your needs and how Collectramatic fryers can be the answer to the challenges you’re facing.