Recently I had a talented chef come to our headquarters in Louisville to do some testing. He was preparing to open a new traditional-style steakhouse in Chicago. Knowing how the competition is for that segment, he needed an ace up his sleeve. He had heard quite a bit about our CVap® technology but wanted to see it for himself. So he came to town with a very specific goal: to test a CVap Cook and Hold Oven side-by-side against a sous vide immersion circulator. He also had some specific food items he wanted to evaluate, so he came with beef, pork, and chicken. I knew I had two days of caveman-style protein consumption to look forward to!

At the risk of over-explaining, let’s define the equipment.

What is a CVap Cook and Hold Oven?

Our cook and hold ovens do exactly that – cook and hold. They’re designed to cook to a precise endpoint temperature, then transition into an automatic hold mode. This frees the user from having to babysit the oven and pull food as soon as it’s done. CVap technology, with its dual heat system, can maintain food at the preferred temperature and doneness level for extended time periods.

CVap ovens are also known for achieving fantastic yields. Cooking low and slow in a CVap can increase yields by as much as two servings on whole roasts. The increased yield can help the oven pay for itself in a brief time.

What is an Immersion Circulator?

An immersion circulator works by heating and circulating water in a container to maintain a precise cooking temperature for sous vide cooking. It allows for consistent and controlled cooking, resulting in tender, flavorful, and evenly cooked food.

The food to be cooked is placed in a vacuum-sealed bag or airtight container. The bag is then submerged in the water bath, and the immersion circulator continues to maintain the set temperature. The immersion circulator keeps the water bath temperature constant, allowing the food to cook slowly and evenly. This gentle and precise cooking method helps retain the natural flavors, textures, and moisture of the food.

Preconceptions

I already had experience with side-by-side testing with the circulator, so I thought I knew what to expect. Wrong. The visiting chef was very detail-oriented and wanted to capture all the results with precise notes and pictures. So that’s how we approached the project. I was surprised by what we found. I already knew about the procedural efficiency and cost savings made possible by choosing CVap over the immersion circulator, but I was not prepared to discover just how much better it performed regarding texture, flavor, and consistency. Time after time we were both surprised after tasting the finished food.

A Precision Cooking Contest

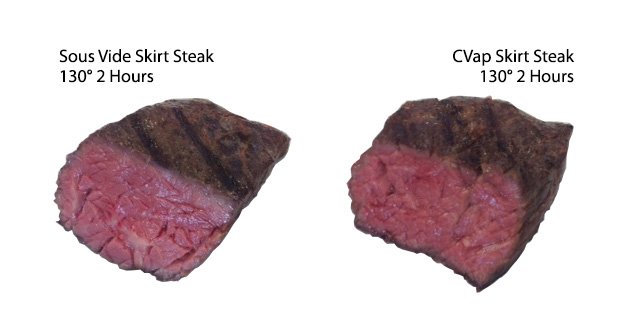

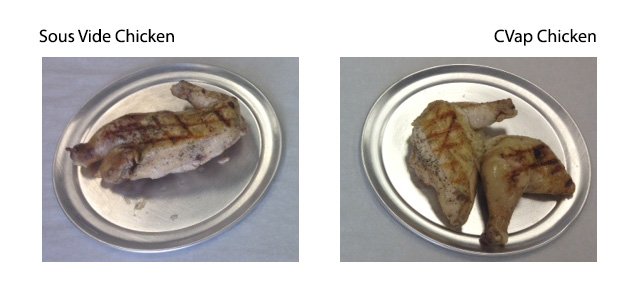

We tried three different methods for each item: bagged in immersion circulator; bagged in CVap, and bagless in CVap. The menu included short ribs, mock tenders, beef filets, ribeye steaks, NY strip steaks, skirt steaks, and half chickens.

Each product was cooked and finished. The results for each product weighed heavily in favor of the bagless CVap sous vide process in terms of flavor, texture, consistency, and moisture retention. Each CVap protein was more tender and easier to handle than the more complex traditional bagged sous vide process.

Then there’s also the issue of capacity. We realized that he would need at least four circulators to do what we were doing in one half-sized CVap Cook and Hold Oven, which negated the cost difference of the two options. CVap was the least expensive option. Not to mention the continuous cost savings each year of not having to use the plastic products and the labor savings during prep time without the need for bagging the food items.

Key Differences Between a CVap and an Immersion Circulator

Although CVap ovens and immersion circulators both cook with heated water (or heated water vapor), the similarities stop there. Let’s look at the key differences.

To Bag, or Not to Bag

The use of vacuum bags is a key difference between the two appliances. The immersion circulator requires food to be vacuum-sealed in food-safe bags before being placed in the circulator for cooking. On the other hand, CVap ovens make it optional. If desired, the user can bag food before cooking in CVap. But it’s not required. Because CVap uses heated water vapor as its primary heat source, it’s equally effective with or without the bags. Eliminating the bags also eliminates a lot of waste (and plastic for the landfill). Likewise, going bagless also reduces the labor required for prep.

Capacity (or Lack Thereof)

Another key difference between CVap and circulators is capacity. A half-size CVap oven can hold five shelves of food products. That’s a substantial amount of food in a small footprint (about six square feet). As we mentioned before, it took four circulators to equal the capacity of one half-size CVap oven. Unless you have copious counter space, it quickly becomes an issue.

It’s a Liquid, It’s a Gas

There’s a significant difference in the physical state of the water used in CVap ovens and immersion circulators. As the name implies, immersion circulators require food to be submerged in heated water to cook. This is why food must be bagged prior to cooking sous vide in the circulator.

CVap technology does involve a water reservoir (or as we call it, an evaporator) being heated to the specified temperature. But food is never placed in that reservoir. The cooking is accomplished with water vapor. We figured out years ago that heated vapor would naturally equal the temperature of the evaporator’s water and carry just as much heat energy. Paired with a secondary air heat system, CVap’s dual heat system is unrivaled at its precision and reliability.

No One-Trick Pony

Our testing confirmed CVap’s bagless sous vide method produced superior results over traditional bagged sous vide in a circulator. But another thing to consider is the fact that immersion circulators can only cook sous vide. No other cooking methods are possible.

On the other hand, CVap is capable of a vast range of cooking methods. Sous vide, baking, steaming, roasting, holding, braising…you name it, it can probably be done in a CVap oven. Contact us today to learn more about how CVap can help your operation.